QUV Waterway Maintenance

1.Cleaning the Water Tray

For QUV testers equipped with a condensation system, the water tray should be inspected and cleaned every six months.

If tap water is used in the QUV/se, the equipment should be inspected and cleaned more frequently.

When there is scum on the water surface or sediment at the bottom of the water tray, clean the water tray and replace the water.

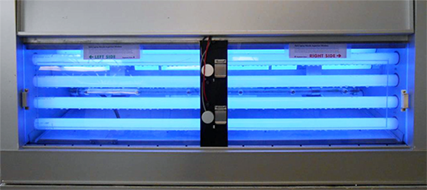

Remove the lamps and the top cover to easily clean the water tray, as shown in the figure below:

.png)

2.Inspect QUV/spray nozzles

Each QUV/spray unit is equipped with spray inspection windows. The left and right spray inspection windows can be used to check whether the nozzles are blocked. The nozzles should be inspected monthly: remove all test panels from one side of the QUV unit, and place the inspection windows on both left and right sides in position; run the spray step, and the specified area of each inspection window should be in a wet state; repeat this procedure on the other side of the machine.

If part of the specified spray area on the inspection window is not wetted, the nozzle corresponding to that area should be removed and cleaned. A small brush and compressed air can be used to clean the nozzle.

3.Inspect filters and others

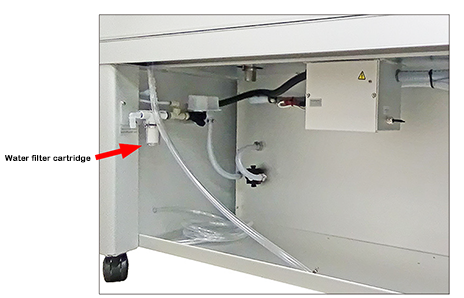

The water filter cartridge should be inspected every 6 months. If the cartridge is dirty, it should be replaced.

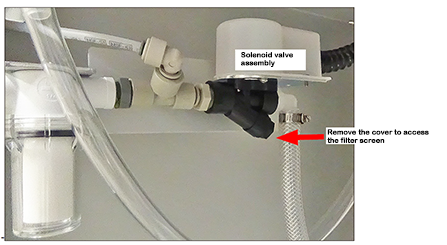

The solenoid valve filter screen should be inspected every 6 months. If the filter screen is dirty, clean it with a clean small brush.

The above operations are described in detail with step-by-step instructions and guidance in the product manual provided with the machine. For the product manual or any other assistance, please contact us!