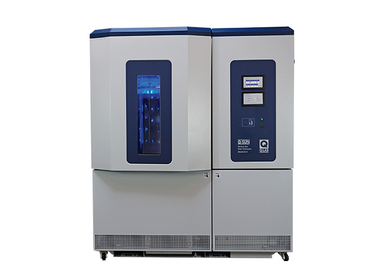

QUV Accelerated Weathering Tester

.png) Test plastics, coatings, and other materials for durability when exposed to outdoor sunlight, heat, and water

Test plastics, coatings, and other materials for durability when exposed to outdoor sunlight, heat, and water

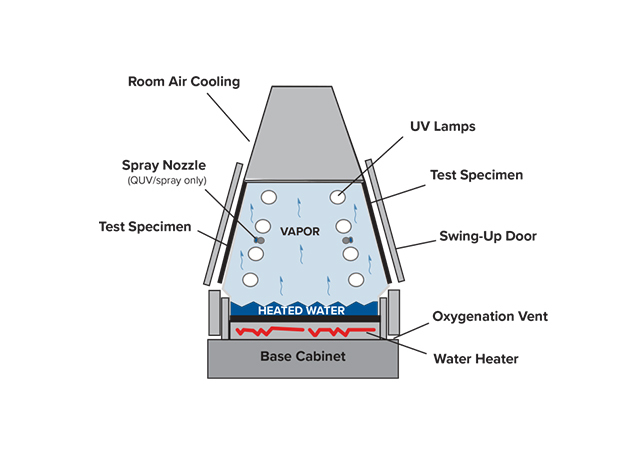

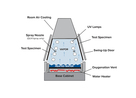

UV light is responsible for almost all photodegradation of durable materials exposed outdoors. The QUV tester’s fluorescent lamps simulate the critical short-wave UV region of the solar spectrum and realistically reproduce the physical property damage caused by sunlight. Types of damage include color change, gloss loss, chalking, cracking, crazing, hazing, blistering, embrittlement, strength loss, and oxidation.

Dew, not rain, is responsible for most of the wetness that occurs in outdoor exposure. The QUV test chamber's condensation system realistically simulates dew and accelerates its effect using elevated temperature.

The condensation process automatically purifies the ordinary tap water used in the system. This is because the process of evaporating and condensing the water onto the specimens is actually a distillation process, which removes all impurities.

The QUV tester conveniently accommodates up to 48 specimens (75 × 150 mm) and complies with a wide range of international, national, and industry specifications, ensuring the reliability and reproducibility of your test program. Visit our standards search for more information.

Easy to Use

The QUV tester’s simple, proven design makes it easy to install, easy to use, and almost maintenance-free. The QUV tester is completely automated and can operate continuously, 24 hours per day, 7 days per week. Other features include:

※ Remarkably simple user interface in 17 user-selectable languages: English, Spanish, French, German, Italian, Japanese, Chinese, Korean, Czech, Dutch, Polish, Portuguese, Russian, Swedish, Thai, Turkish, Vietnamese

※ Built-in Ethernet connection for data logging

※ Comprehensive self-diagnostic warnings and service reminders

※ Quick and easy calibration with patented AUTOCAL system

※ Designed for safety in operation, calibration and maintenance

Affordable

The QUV tester is economical to purchase and to operate. It features low-cost, long-life fluorescent UV lamps and uses ordinary tap water for condensation.

Models

● QUV/basic: UV and condensation (no irradiance control, single touchscreen display)

● QUV/se: UV, condensation, and SOLAR EYE irradiance control

● QUV/spray: UV, condensation, SOLAR EYE irradiance control, and water spray

● QUV/uvc: short-wave UVC light and SOLAR EYE irradiance control

● QUV/cw: cool white visible light, condensation, and SOLAR EYE irradiance control

Features

QUV/se

The most popular QUV model features SOLAR EYE Irradiance Control, for precise maintenance of UV light intensity. The QUV/se tester uses a proven condensation mechanism to simulate outdoor moisture attack.

The SOLAR EYE system is a precision control system that automatically maintains light intensity through a feedback loop. The controller monitors UV intensity and compensates for lamp aging and variability by adjusting power to the lamps. The SOLAR EYE system provides:

Controlled irradiance

Longer lamp life

Faster results

More reproducible and repeatable testing

ISO-compliant calibration

QUV/spray

The QUV/spray tester performs all the same functions as a standard QUV/se tester, plus direct water spray. Short periods of spray can be used to create thermal shock. Longer periods of spray can be used to achieve mechanical erosion. The QUV/spray tester can be set to produce UV, spray, condensation, and functions combining UV and water. Purified, deionized water is recommended for all spray applications.

QUV/uvc

UVC light is used widely in ultraviolet germicidal irradiation (UVGI), a technique used to eliminate harmful viruses and bacteria. This short-wavelength, high-energy UVC light can also degrade the materials and surfaces it disinfects. The QUV/uvc model uses UVC lamps to deliver light concentrated at 254 nm to test for material durability against photodegradation effects resulting from exposure to UVC light. The QUV/uvc tester has multiple safety features to prevent stray UVC light from escaping. It is not equipped with condensation or water spray.

QUV/cw

Some industry test methods specify the use of cool white fluorescent lamps for indoor photostability testing. To reproduce these indoor light conditions, the QUV/cw uses ordinary cool white fluorescent lamps. It has a SOLAR EYE irradiance control system that monitors and controls visible light output, rather than UV.

QUV/basic

This is a simplified version of the QUV tester for laboratories where economy is critical. The QUV/basic tester uses fluorescent UV lamps and a condensation system for moisture simulation. It does not, however, include SOLAR EYE irradiance control. Consequently, the light intensity cannot be adjusted or calibrated. This means the QUV/basic tester cannot be used for high irradiance testing. In addition, periodic lamp replacement and repositioning is required.

Q-Lab recommends the QUV/basic tester only for comparative exposures where the test specimens and the control specimens are exposed at the same time, in the same tester.

Temperature Monitoring & Control

All QUV accelerated weathering testers precisely control temperature to enhance accuracy and accelerate test results. Although temperature does not normally affect primary photochemical reactions, it does affect the rate of any subsequent reactions. Therefore, the QUV tester’s ability to control temperature is essential during UV exposure.

Versatile Specimen Mounting

Versatile Specimen Mounting

Standard specimen holders easily adjust for any thickness up to 20 mm (3/4 in) and allow fast, snap-action specimen mounting. Retaining rings provide positive hold-down and do not require that test specimens be cut to close tolerance. In addition, custom holders are available for mounting various products, such as lenses, larger specimens, and 3D components.

SOLAR EYE Irradiance Control

The SOLAR EYE irradiance control system constantly monitors and controls lamp output. This assures precise light exposure and maximizes reproducibility of test results.

Software & Operations

The QUV accelerated weathering tester’s displays are designed to be both functional and easy-to-use. QUV testers feature dual, full-color touchscreen displays (except QUV/basic, which has a single touchscreen display) and can be programmed in 17 user-selectable languages (English, French, Spanish, Italian, German, Chinese, Korean, Japanese, Czech, Dutch, Polish, Portuguese, Russian, Swedish, Thai, Turkish, and Vietnamese). This system includes complete self-diagnostic error checking, constantly monitoring the status and performance of all systems. It also displays tester error messages and routine service reminders as needed. The multicolor LED status indicator light updates users on the tester’s operational state at a glance.

Calibration

Temperature Calibration

The QUV black panel temperature sensor needs to be calibrated periodically by the user to assure accurate and consistent results. Calibrating the QUV black panel temperature sensor is quick and simple, and is performed with any standard reference thermometer.

Irradiance Calibration

For all models except QUV/basic, the QUV SOLAR EYE irradiance sensors need to be calibrated periodically by the user to assure accurate and consistent results. Calibrating the QUV tester is simple using the Universal Calibrator system’s UC10 calibration radiometer, and takes only a few minutes. Three models of UC10 irradiance smart sensors are available:

UC10/UV - for use with UVA-340, UVA-351, UVB-313, and TUV-421 lamps (plus and non-plus versions)

UC10/UVC – for use only with UVC-254 lamps

UC10/CW - for use only with Cool White lamps

ISO 17025 Accredited Recalibration

Calibration of UC10 radiometers needs to be performed annually. UC10 radiometers were designed to be disposable and cost-efficient, and can either be replaced annually with a freshly-calibrated sensor or returned to Q-Lab once per year for an inexpensive recalibration.

Q-Lab's calibration labs in the United States, Germany, United Kingdom, and China are ISO 17025 accredited by the American Association of Laboratory Accreditation (A2LA) to perform calibrations of UC sensors. Calibrations are traceable to the United States' National Institute of Standards and Technology (NIST).

USA

USA