500-Hour Maintenance: Calibrate Irradiance(QUV)

To prevent the aging of the lamps and the irradiance sensor of the equipment itself, it is required to calibrate with an external calibrator every 500 hours. This addresses the issue of irradiance deviation caused by factors such as lamp attenuation and aging, ensuring the accuracy of irradiance. When the equipment displays the message "M66 Time to Calibrate", you should calibrate the equipment using an irradiance calibrator.

The QUV ultraviolet aging tester is divided into the following three types of calibrators and calibration methods based on machine models from different eras:

1.Integrated calibrator and its calibration method

.png)

.png)

2.Split-type universal calibrator calibration method

.png)

.png)

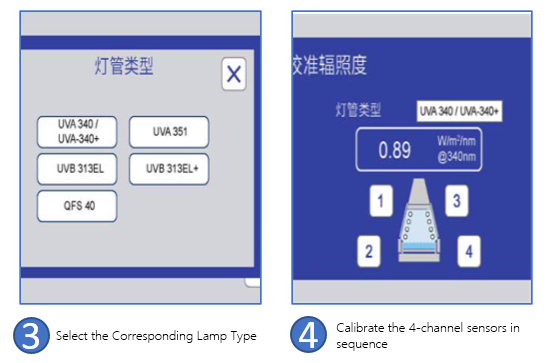

3.Touchscreen version calibration method

Tips:

● The position for placing four monitoring point sensors in the middle of the QUV sample placement area can be found on both sides of the machine.

● To obtain the most accurate results, ensure the QUV has reached the normal temperature setpoint before calibration. For example, if the UV temperature is set to 60°C, make sure the temperature has reached 60°C prior to calibration.

● Select the lamp type via the calibrator and the lamp type button on the screen, ensuring the selected lamp type matches the one used by the QUV.

● Press and hold the calibration key until a beep is heard. After a few seconds, the irradiance value displayed on the machine should match that on the calibrator. If not, press and hold the calibration key again.

● Even if the values on the calibrator and the machine match during each calibration, you still need to press and hold the calibration key to calibrate. Only then will the calibration reminder message disappear.

The above operations are detailed with step-by-step instructions in the accompanying product manual. If you need this product manual or other assistance, please contact us!