AATCC TM 183: Test Standard for Ultraviolet Protection Factor (UPF) of Fabrics

1.Scope of Application

This test method is used to evaluate the ability of fabrics used in making UV-radiation protective textiles to block or transmit ultraviolet (UV) radiation.

This test method can be used to measure the UV-protective performance of samples in both dry and wet states.

2.Testing Principle

The ultraviolet radiation UV-R (280-400nm) passing through the sample is measured by a spectrophotometer or a spectroradiometer with a known wavelength range.

The Ultraviolet Protection Factor (UPF) is calculated based on the ratio of the average effect of UV-R radiation calculated when passing through air to that calculated when passing through the sample.

The percentage of irradiance blocking for UV-A and UV-B is tested.

3.Testing Instruments

Spectrophotometer or UPF UV transmittance tester equipped with an integrating sphere.

Filter: Schott Class UG11

Clean plastic food wrap for wet-state samples.

AATCC absorbent paper

4.Instrument Calibration

4.1 Calibration: Calibrate the spectrophotometer or spectroradiometer according to the manufacturer's instructions. It is recommended to use physical standards to confirm the measurement of spectral transmittance. When testing wet-state samples, cover the observation port with plastic film and re-calibrate.

4.2 Wavelength Scale: Calibrate the wavelength scale of the spectrophotometer or spectroradiometer using the radiation spectrum emitted by a mercury vapor discharge lamp. The wavelength of the spectrophotometer or spectroradiometer can be calibrated using the absorption spectrum of a holmium oxide glass filter. For details, refer to ASTM E 275.

4.3 Transmittance Scale: When no sample is placed in the light path, set the transmittance scale to 100%, which is the transmittance relative to air. The zero transmittance scale can be calibrated by blocking the light path with an opaque material. The linearity of the transmittance scale can be confirmed using neutral filters or calibration multi-cell plates provided by the instrument manufacturer or a standardization laboratory.

5.Sample Preparation

5.1 At least two samples should be tested from each piece of fabric for dry and wet state testing. Each sample should have a size of at least 50mm×50mm or a circle with a diameter of 50mm. Do not twist the samples during preparation and handling.

If the sample includes different colors and structures, each color and structure should be tested, and the size of each sample should be sufficient to cover the test points.

5.2 For fluorescent samples, the dyes or optical brighteners in the fabric may affect the measurement of spectral transmission, potentially causing artificially higher results.

6.Test Conditioning

For dry samples.

Before testing, precondition the samples as described in ASTM D 1776. Each test sample shall be placed in a standard atmosphere of 21°C ± 1°C and 65% ± 2% relative humidity for at least 4 hours. Each sample should be individually placed on a perforated screen rack or a placement rack.

7.Testing Method

7.1Dry State Testing

Place the sample directly on the sample transmission end of the integrating sphere.

First, measure the sample in any direction, then rotate it by 45° for testing, and then rotate it by another 45° for testing. Record each result separately.

For samples with multiple colors, test the area with the highest UV transmittance and measure three values in this area.

7.2Wet State Testing

Fully immerse the sample in water and soak for 30 minutes, periodically squeezing the sample to ensure uniform and complete wetting.

Place the wet sample between two sheets of absorbent paper, then squeeze it in a padder or similar device to achieve a moisture content of 150% ± 5%. Proceed to testing.

Cover the observation port with plastic film to prevent water from contacting the instrument and ensure the sample maintains the specified moisture content.

8.Calculation

① Calculate the average spectral transmittance of the three test values for each sample.

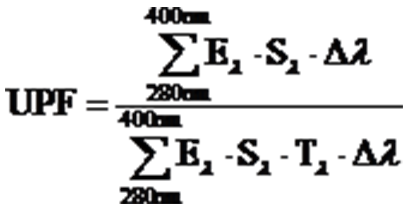

② Calculate the Ultraviolet Protection Factor (UPF) for each sample:

Where:

Eλ — Relative erythemal spectral effectiveness

Sλ — Solar spectral irradiance

Tλ — Average spectral transmittance of the sample (measured)

Δλ — Wavelength interval of detection

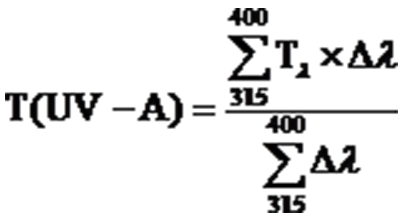

③ Calculate the average UV-A transmittance:

④ Calculate the average UV-B transmittance:

.png)

⑤ UV-A and UV-B blocking rate

9.Report

① Ultraviolet Protection Factor (UPF).

② UV-A transmittance.

③ UV-B transmittance.

④ UV-A blocking rate.

⑤ UV-B blocking rate.

⑥ If the moisture content is higher than 150%, report the actual moisture content.

The above information is compiled from the Internet for reference and learning only. For the complete AATCC Test Method 183 standard, please call Luozhong Technology at 021-61485255.